Projects

On-site condition monitoring

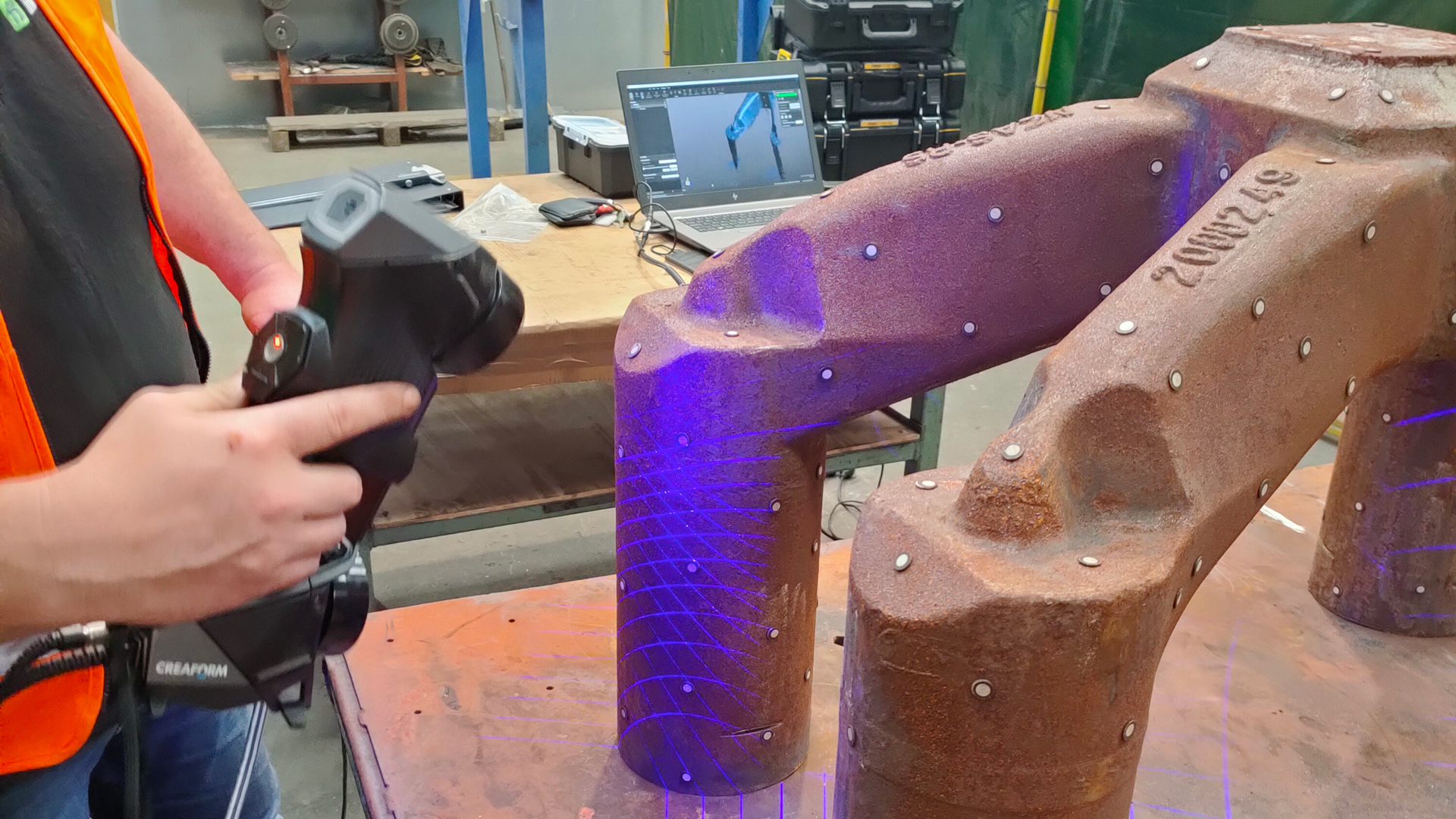

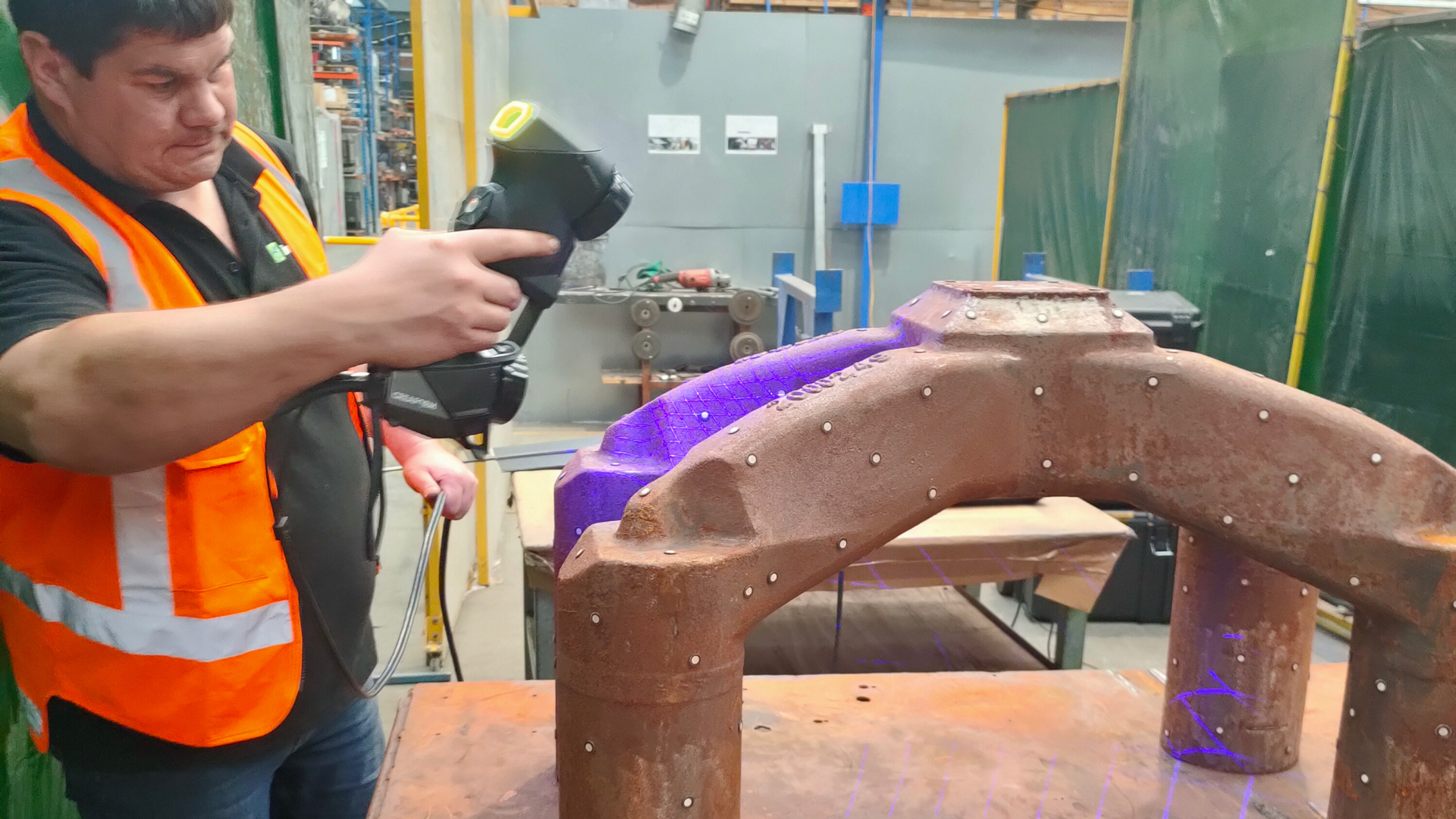

Here is Derek on-site scanning an internationally-sourced casting during a condition inspection. In under 5 hours, we 3D-scanned 25 of these anode mounts, checking for tolerance conformity.

Here is Derek on-site scanning an internationally-sourced casting during a condition inspection. In under 5 hours, we 3D-scanned 25 of these anode mounts, checking for tolerance conformity.

Once the super-accurate ‘HandySCAN BLACK Elite’ truly portable scanner has captured the data, we produce a comprehensive report for the client. This report documents the critical dimensions of each casting displays visual images and compares the mounts with the original design specs. Earlier on, we had 3D scanned an unused mount to establish the reference dimensions.

The NZAS team will then assess each mount’s current condition and determine whether to replace or re-use it.

If you're looking at ways to run quality assurance testing for injection mouldings, fabrications, castings or other components, then this is an accurate and affordable option.

12 Jan 2021 - 3D Scanning_ Projects